Microwave Press Extraction Apparatus

Proprietary Microwave Extraction Invention

- Patent Title: Microwave Press Extraction Apparatus

- Jurisdiction: United States Patent and Trademark Office (USPTO)

- Patent Number: US 10,029,435 B2

- Inventor: Idris Ahmed Ali

- Year Granted: 2018

Overview of the Invention

One of the key innovations offered by the company is a novel device for extracting date juice (dibs) from diverse raw date varieties, using microwave energy, invented by the proposer.

The invention utilizes controlled microwave heating to heat up water-date mixtures thus rupturing date cell structures, and releasing juice efficiently. The released juice is further concentrated by microwaves.

The process is adaptable to other fruits and vegetables, opening wider applications beyond dates.

Methods used for Extraction of Date Juice

A. pressing in which the Dates are put in large plastic bags, piled on top of each other and kept in a tightly closed room for weeks and months and the juice is flows down by gravity to be collected at the lower end of the room. This method has many drawbacks among which

- long extraction time, extending for weeks and months,

- sanitary conditions not preserved (extracted juice subject to dust and insects),

- very low yield (10%), dark and turbid juice.

b) The other method, which is used at home and industry is

- Soak dates in boiling water using traditional fuel (gas coal etc.)

- filtering and condensing the remaining filtered juice in open pans.

- Drawbacks

- Use of traditional fuel with its environmental consequences;

- Long extraction and subsequent long concentration time.

Advantages Over Conventional Extraction

The following table illustrates key performance differences between the patented microwave extraction apparatus and conventional extraction methods (traditional extraction/pressing/heat extraction/solvent extraction):

| Criteria | Microwave Extraction (Invented) | Traditional Extraction | Advantage |

|---|---|---|---|

| Energy Consumption | Very low, short contact microwave | Long, prolonged heating requirement | Faster Process |

| Time | Short (within minutes) | Long (hours) | High Yield |

| Nutrient Retention | Excellent – minimal degradation | Lower – longer heating affects quality | Better product quality |

| Yield | Higher yield of juice/oil/oleoresin | Mostly depends on pressure and temperature | High yield |

| Versatility | Can be applied to fruit and vegetables | Mainly depends on fruit & vegetable type | Broad applications |

Prototype Demonstration

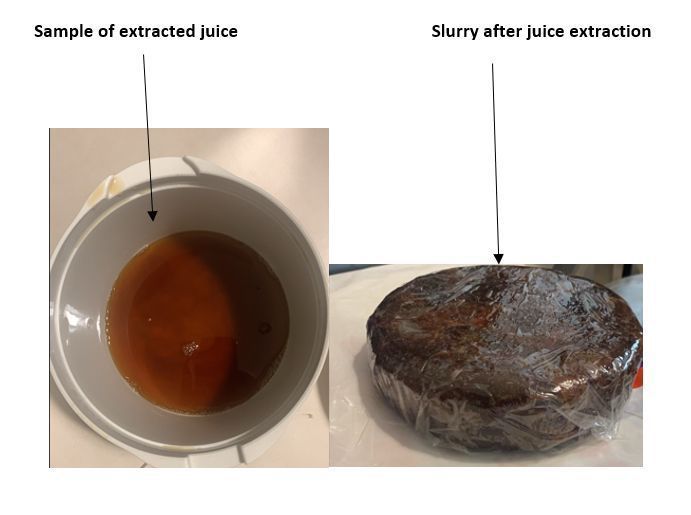

A prototype has been designed, fabricated, and successfully tested.

Design: Custom microwave-assisted extraction system built with integrated temperature and pressure control.

Performance: Demonstrated highly high yields of juice and oil/oleoresin extraction within a short timeframe.

Scalability: Design adaptable to semi-industrial or industrial scale processing.

Sustainability Advantages

- Energy efficiency (50% less energy than traditional heating).

- Reduced solvent use.

- Eco-friendly extraction process.

- A cleaner production technology, ecofriendly, and solvent-free.

- Low environmental impact, faster production time, and energy use.

- Reduces CO₂ emissions.

Areas of Application

- Food industry

- Pharmaceutical industry

- Chemical & Petrochemical industry