Industrial Applications of Microwaves

Examples of Industrial Applications of Microwaves. Are You New Microwave User?

If you’re new to the world of industrial microwaves, and curious about industrial microwave applications we highly recommend you these Typical Examples of industrial applications of microwaves in different fields. You will definitely find yourself in one of them, and we are here to guide you to fulfil your dream application:

Food Industry

Rapid pasteurization & sterilization: Microwaves are used for ready-to-eat meals, baby foods, and dairy products, ensuring microbial safety without destroying flavor and nutrients.

Drying and dehydration: Fruits, herbs, spices, and instant noodles are dried faster and at lower temperatures compared to hot-air drying, preserving color, aroma, and vitamins.

Extraction of bioactive: Microwave-assisted extraction of essential oils, polyphenols, and natural colors from plants offers higher yields and shorter processing times.

Steel Manufacturing

Preheating of steel billets and molds: Microwaves reduce the energy needed to bring steel billets to forging temperature by quickly heating the surface and reducing furnace time.

Sintering of metal powders: Microwave sintering provides uniform heating, reduced grain growth, and energy savings compared to conventional sintering in powder metallurgy.

Descaling and cleaning: Microwaves can assist in removing scale layers from steel surfaces before further processing, reducing the use of chemical treatments.

Petrochemical Industry

Catalyst regeneration: Microwaves rapidly heat and regenerate spent catalysts (e.g., FCC catalysts) with less coke deposition compared to conventional regeneration.

Cracking of hydrocarbons: Research shows microwave-assisted cracking can produce lighter fractions (ethylene, propylene) at lower temperatures and with higher selectivity.

Waste oil recycling: Microwave pyrolysis of waste lubricants or crude sludge converts them into usable fuel oils and valuable gases with reduced processing time.

Plastics Recycling

Microwave-assisted pyrolysis: Converts plastic waste (PE, PP, PET) into fuel oils, syngas, and waxes more efficiently than thermal pyrolysis.

Selective heating of composites: Microwaves can target the polymer matrix in fiber-reinforced plastics, allowing easier separation and recovery of carbon fibers or glass fibers.

Depolymerization: PET bottles can be broken down to monomers using microwave heating, enabling closed-loop recycling.

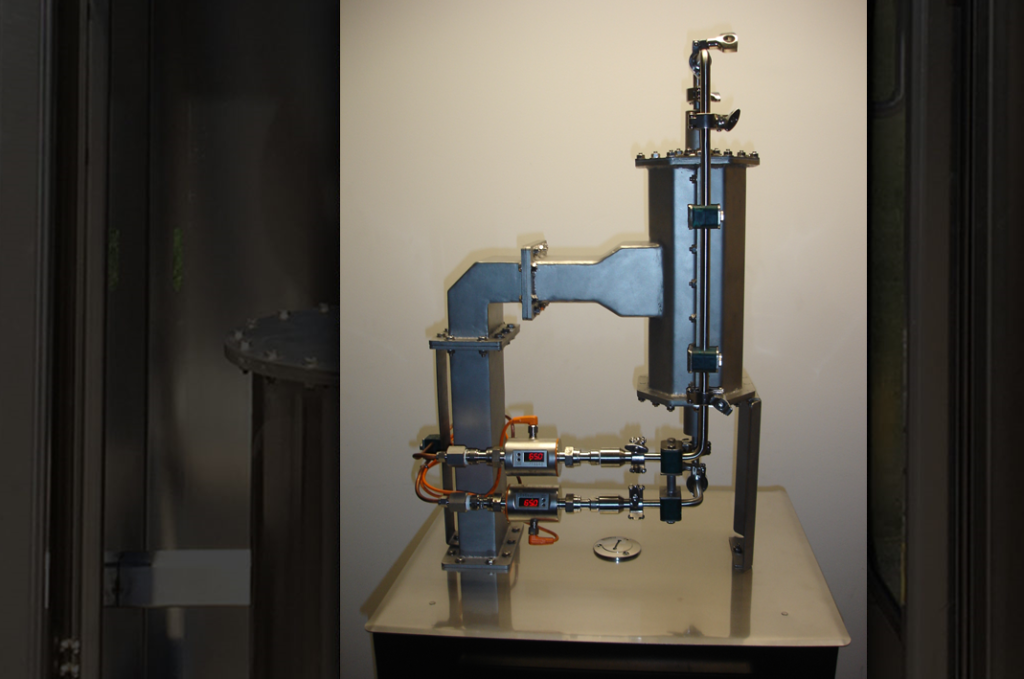

Vacuum Drying

Pharmaceuticals & biotech products: Microwaves under vacuum enable gentle drying of heat-sensitive compounds, preserving activity of enzymes, proteins, and probiotics.

Wood and construction materials: Vacuum–microwave drying removes water efficiently from large timber sections, preventing cracks and improving quality.

High-value foods: Coffee, berries, mushrooms, and freeze-dried meals dry much faster under microwave-vacuum, with superior retention of flavor, color, and aroma compared to freeze-drying alone.